A new product development process typically starts with a design opportunity, which essentially is the realization that you have a chance to introduce a new product that offers a solution to an existing user problem. You then connect with a new product design team, asking for a certain product to be developed, prototyped, tested, manufactured, and finally launched to the market. Design opportunities may arise out of unmet needs or unrealized market demand for a better alternative to an existing product. The design team will set out to analyze the viability of the idea. If there’s indeed a design opportunity, the development can quickly move on to the next phase.

While the process itself is important, a great product is more likely to come out of the work of a great design team as well. Most design teams apply pretty much the same development process, from research and ideation to iterative prototyping and manufacturing. But not all of them have an equal level of expertise and experience to execute every phase of the process well enough to deliver a brief, accurate product design. And when it comes to hiring a design team to handle a new product development, Cad Crowd is bar none the most comprehensive freelancing platform to help you discover multidisciplinary professionals with the know-how to transform ideas and concepts into tangible market-ready products.

RELATED: Designing for Visual Impact with Your Product Design Services Company

Research

Each and every phase of a product development process holds an important role in determining success, but the research part must be singled out as the biggest contributor to the way the project moves forward. The information you gather as a product designer during the research phase will define and affect all the major points throughout the undertaking, from design specification and prototyping to manufacturing and even post-launch product management. Research primarily involves taking a deeper look into the design opportunity to better understand and clarify what the consumers want.

Main focus areas may include an analysis of competitors’ products (or anything that basically offers a similar solution), an exploration of the available and feasible materials to make the product, and an assessment of potential manufacturing methods. A lot of the details that emerge from the research may help you gain new knowledge about the market, price points, factory partners, marketing strategies, and other aspects of product discovery that influence many design decisions later on.

It’s just near impossible to launch a new product development without research, as it opens the door to an in-depth awareness of the contexts surrounding the project, including the business goals, market landscape, target consumers, quality standards, buyers’ expectations, brand identity, and so forth. All these contexts will be used as the foundation of every design decision to keep you on the right track and ensure that the eventual product is something people actually want.

RELATED: How Innovative Design Techniques Can Supercharge Your New Product Concept

Feasibility study

The discovery of a design opportunity brings the excitement of a potential for market success. But it’s important to remember that not every idea leads to a great product. You must first validate the design opportunity by conducting a proper feasibility study and an inquiry into the real-world market demand. A feasibility study is especially crucial when you’re developing a physical product. Bear in mind that you’ll be spending a lot of time and money creating a product and releasing it into the market for people to buy. This is how you regain the initial investment and eventually make profits.

In order to make as much profit as possible, the product designed by expert new concept design & product development firms needs to offer real value to consumers (so it sells in high numbers) while keeping the production cost low. And within the realm of manufacturing, mass production brings down the cost per unit. It follows the same basic formula of “total production cost divided by the number of units produced,” which roughly translates to “the more units you produce, the lower you have to pay for the manufacturing of each unit.

Suppose your new product is a water bottle. In all likelihood, you’ll release thousands of those water bottles into the market at launch. You’ve already spent a vast amount of money researching, developing, and prototyping the product, so you might as well manufacture it in high volume, allowing you to sell each unit at a reasonable price and gain a competitive advantage. Because you’re entering a market already flooded by similar products, a proper balance between quality and price is a clever strategy to give your brand a fighting chance in the competitive landscape.

In the absence of a feasibility study, you blindly send the products to compete with existing alternatives. If the product fails to generate interest among consumers and sells poorly, much of the money you’ve poured into the development is as good as gone. You can’t improve the design when the products are already on store shelves. Unlike software or apps that can receive patches to fix bugs, a physical product comes with a greater sense of urgency to be done right the first time.

RELATED: From sketch to prototype with product design services for companies at Cad Crowd

A feasibility study isn’t just about figuring out whether the water battle can be produced, but it also concerns the business side of product development. Other than an analysis of potential market demand and competitors’ products, the study should include a comprehensive risk assessment as well. There needs to be an encompassing evaluation for financial risks that may emerge from technical challenges, environmental impacts, operational costs, legal issues, etc.

An accurate estimation of product development cost can provide hints into the financial viability of a product; this is where you calculate how much financial investment the development takes, the cost of production per unit, and the amount of money you make for every unit sold. This information enables the design team (or project manager) to come up with an effective plan for resource allocation. Does the design team have enough budget and human resources to ensure a successful product development? If resources are tight, is there any way to keep the development running more efficiently?

Idea generation

Every product people see and use every day starts as an idea. Some say an idea can arrive out of nowhere and lead you to an innovative product design the market has never seen before, but product developers can’t always count on such a sudden brainwave. It doesn’t happen too often, and when it does, there’s no guarantee it’s a good one. Following the research phase, the design team should gather for an idea generation session. At the very least, the session should involve the project manager, the designer, and the engineer. An ideation phase is meant to generate as many product concepts as possible from differing perspectives.

The main purpose isn’t to define how the final product should look and what features it needs, but to come up with multiple available design options that align with the market demand. An idea generation doesn’t have to be a sophisticated process. It can be as simple as a brainstorming session supplemented by social media exploration and Internet search. Make sure to write down the ideas in an organized fashion, so you can keep track of everything, because you will have to refer back to the notes repeatedly over the course of the session. Sketches and drawings created by CAD drafting professionals (with annotations) are simple yet probably the most effective tools for the job.

RELATED: Top 31 Websites to Hire Concept Design Experts and CAD Engineers for Companies & Firms

Don’t even think about using CAD software. You don’t need it at this point, but you will definitely use it later in the development process. If you want to be a bit more elaborate, the design team can take advantage of tools like Facebook Groups or online forums to conduct surveys. However, you’re not asking the public to give you ideas; the surveys are intended as communication channels to discover consumers’ interest in new products, pain points they experience with the existing products, what features they want, and so on. You can then formulate ideas based on the information.

Back in the research phase, you’ve already defined what problem the product is supposed to solve. Keep in mind that a product can only become an attractive option to the existing alternatives if it offers a good solution to a problem. The idea generation phase must therefore strive to discover a viable design that may take care of this problem in an easy, practical, and affordable manner. That being said, an effective ideation also needs to be judgment-free, meaning everyone is encouraged to come up with any suggestion or concept of a product. Some of those ideas will be bad, others are terrible, but a few concepts may seem promising enough. The focus is on quantity, not quality, so everything is welcome so long as it still makes sense.

Idea screening

Never confuse “idea generation” with “idea screening,” as the latter needs a completely different approach from the former. While they’re both intended to discover viable product design, idea screening is where every single concept generated during the previous phase will be scrutinized for technical and financial feasibility. At the end of the screening process, it’s expected that the consumer product design team has put aside all the ideas that are not going to work, either because it’s implausible from a technical point of view or due to budget constraints. A proper screening prevents you from spending time and money on something that’s highly unlikely to materialize.

It’s better to narrow down the options to the most promising and realistic design, so you can utilize the resources more effectively. Ideas are not actually that difficult to generate; what’s difficult is choosing the right one to develop further. Because a new product development process is almost always an expensive venture, the design team must establish an efficient strategy to manage ideas and implement prioritization. Ideally, only the best option deserves resource allocation.

RELATED: Best Tips for Creating a New Invention or New Product Design

For example, during an idea generation for a new water bottle, there are more than 20 ideas with sketches and drawings recorded by the CAD drawing expert. In an attempt to be unique or striking, one member of the design team created a concept of a sports water bottle made entirely out of stained-glass materials. It’s not technically impossible, but carrying such a brittle product for outdoor activities isn’t exactly popular. Another member suggests a design of an otherwise typical water bottle, except that the lid is positioned in the middle rather than at the top as normally expected. The design should dismiss those ideas and look for something better.

A scoring system can make idea screening easier. Rate the product based on such factors as manufacturability, potential market size, and alignment with the design team’s capabilities. Features and usability must be taken into consideration as well. For instance, the ideal water bottle should be easy to use, clean, refill, and carry. The materials should be safe, durable, and easily sourced. As for the aesthetics, don’t forget to include ergonomics (the shape and form of the product) into the equation, too. The idea that ends up at the top of the scoring system is the one worth developing.

Working backwards

Sometimes, it pays to use the “working backwards” technique during the idea generation and screening phases, although this is mostly reserved for the more complex products like electronics or mechanical implements. As the name suggests, the technique requires you to start from the endpoint of a design process. Suppose you want to build the thinnest Bluetooth-enabled stereo speaker in the market; the 3D product modeling team uses a sketch or a 3D model of the product in question, and then works backward to figure out the necessary engineering steps to achieve the design.

Design specification

With the market research and ideation phases done, it’s now time to focus on the best concept selected from the screening process. At this point in the development, even the best concept still only represents a rough notion of a product. Everything is imprecise and will need a lot of work until it actually resembles a refined concept. A big part of the work is to define the product specification, which may include details like dimensions, materials, aesthetics (colors, ergonomics, textures, etc.), and cost. Depending on the product type, a design specification may contain information about functionality, technologies to be utilized to fabricate or manufacture the product, and how the product should be used.

RELATED: Innovation Best Practices: Strategies for Better & Faster Product Design Services

Design specification is all about defining the product’s function and form, as well as the user experience it should deliver. The purpose is for the product engineer to create a workable concept that can be feasibly developed into a user-friendly product. More importantly, the concept can give you a clear vision of how this product will provide a solution to an existing problem. Design specification isn’t always final; the concept created from this phase doesn’t necessarily represent the market-ready product. There might be multiple rounds of refinements and changes at a later date, especially after prototyping and testing phases.

Concept development

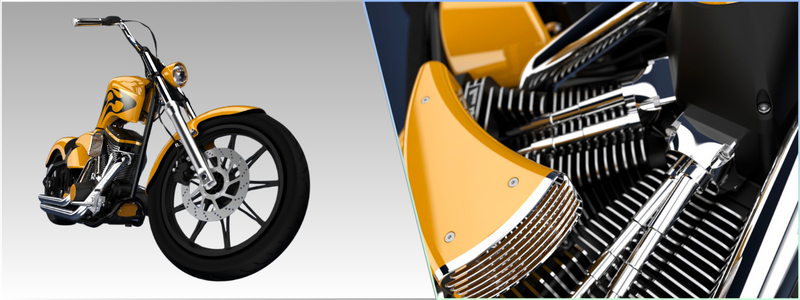

A follow-up on the design specification phase, the team embarks on concept development work to transform the idea into something a little bit more concrete. You’re not creating a prototype here, but a digital visualization of the product drawn on a computer screen using CAD software. 3D modeling design services are much more preferable than two-dimensional sketches as it offers a clear visualization of the product’s physical shape. The initial mock-up might not look realistic, but at least it can accurately represent the form and proportion/dimension.

Once the wireframe model has been created, the design team can keep on refining the concept by giving it additional details such as colors, textures, and patterns on the surface to achieve a more lifelike appearance. The vast majority of modern 3D CAD software packages offer the option to mimic the looks of various materials such as metal, plastics, woods, stones, and so forth. No matter what you make, make sure every little detail is drawn in accordance with the design specification.

But a product concept development isn’t only about translating the design specification into a 3D visualization design. It’s also about evaluation. The digital mock-up allows the design team to present the concept in a much more discernible format to stakeholders. Having a clear visualization of a product concept as a presentation tool makes it easier to elicit feedback from everyone involved in the project. If you can see and understand the concept, you’re likely to notice whether the design team has done something that accurately aligns with the project brief or misses the mark. Either way, you (as a client) can give honest feedback to the team.

RELATED: Top 51 3D Product Rendering Design & Best 3D Visualization Services Companies in the US

It may take a few rounds of feedback and refinements throughout the concept development phase. The additional insights and criticisms from the stakeholders enable the team to iterate on the design in the hope of discovering the optimal solution. The good thing is that all the modifications to the mock-up happen on a computer screen. There’s no physical object involved in this process to save time and money. The goal is to address potential flaws at the earliest time possible and build an aesthetic design that can differentiate the product from all others in the market.

Business analysis

With the final concept in hand, the next logical step is to analyze and calculate how much money it will take for the product design expert to transform the concept into a physical product. Although it’s difficult to be precise about it, at least the design team has a rough idea of the amount of money (and other resources) required to bring the concept to life. Among the major points of consideration are the cost for prototyping and manufacturing. An experienced design team should be able to provide an estimate, allowing you to set a maximum budget limit to avoid overspending. Based on the available budget, the project manager can set a course of action to make the best of the provided resources.

Prototyping

Certainly, the most exciting step of a new product design process, the prototyping phase, is where the concept transforms into a physical object. A prototype is an early version of a product, with a lot of imperfections. The idea behind physical prototyping is to give the prototype design team the chance to run multiple tests to see if the product looks and works as intended. It sounds like a fun (and potentially expensive) experiment depending on how well the prototype performs, but there can be various mishaps such as dimension errors, poor ergonomics, feature malfunctions, and so forth.

Many things can go wrong, but every discovery of a mistake is a lesson that yields valuable insights into creative solutions. By far, the most widely used prototyping methods are 3D printing services and CNC machining. Each has its own advantages and drawbacks, depending on the nature of the product itself. For example, 3D printing is great for creating a physical prototype made entirely of plastic material. Thanks to the proliferation of consumer-grade 3D printers, it has now become easier, quicker, and more affordable to create a physical object from a CAD file. CNC machining is just as accurate, but the method is mostly intended for a prototype made of metal.

RELATED: Designing Prototypes: 3D Design Services for Inventors and Companies

Simulations

Computer simulation software actually allows you to test a product without having a physical prototype. In essence, the technique requires you to build an accurate 3D model (of the product) and run it through many different virtual usage scenarios and stress tests. Popular tools such as Finite Element Analysis (FEA) engineering services and Computational Fluid Dynamics (CFD) offer a detailed overview of product or material behavior when exposed to real-world forces, for instance, exposure to extreme temperatures, electromagnetics, vibration, and weight or load. Virtual simulations help designers and engineers identify weak points in a product assembly and discover room for improvement without creating a physical prototype.

Testing and iteration

Virtual simulations are great and all, but a physical prototype remains a crucial point in a product design process. A physical prototype is still the best way to understand real-world user experience and feel the ergonomics of a design. You need to know if the product actually is easy-to-use and does offer an effective solution to a user problem. Regardless of the prototyping method used, a new product development is always an iterative process. A physical prototype provides clues as to how to make the next one better in every aspect, including usability, safety, durability, and functionality. Note that you may need more than several rounds of testing and iteration before the product achieves its optimal design.

Manufacturing

At the end of the prototyping phase, you have a final design ready to be mass-produced. The design for manufacturing and assembly team collaborates with a manufacturing partner to make sure that the production units are identical to the final prototype. Every detail from the materials, dimensions, forms, functionality, and appearance of the mass-produced units will go through a quality assurance process to verify the overall build quality and performance. Once everything is verified, the product is ready for market launch.

RELATED: DFM For New Product Design Excellence: Complete Guide for Company Success

How Cad Crowd can help

A successful new product design process requires a well-balanced combination of creativity, excellent attention to detail, financial sensibility, persistence, and excellent project management skills. From the moment you bump into a design opportunity all the way to the manufacturing process, things might not always run smoothly without occasional mishaps. The mark of a great team is to handle every setback with a positive attitude and a willingness to strive for innovations and effective solutions. And as previously mentioned, you’ll be hard-pressed to find a more extensive platform for hiring professional product designers than Cad Crowd. Get a free quote today!